Our services

Digital Printing

Transfer Printing

Our priority as a company is to give priority to customer satisfaction by giving the least damage to the environment and to offer fast and affordable products that comply with the quality standards.

Digital Textile Printing is a type of printing that has become widespread after the second half of the 2000s. The difference from traditional screen printing is that it obtains high number of colors from the use of CMYK and white pigment inks and is a 100 percent organic print with high resolution. Digital textile printing is an alternative to screen printing, including quantity and piece printing, more economical in the long term, and a longer-term printing type in terms of touch and usage. In today's textile industry, it is rapidly progressing to become the most preferred printing type because it does not disturb the ecological balance in the usage process and is more economical in the long term. While it had a share of 9% in printing types used worldwide in 2009, it had a share of 18% in 2011 and 30% at the end of 2012.Digital textile printing will continue its rapid rise in the face of screen printing because traditional screen printing repeats itself and cannot offer something different to customers, turns to cheap labor and cheap materials to reduce costs, and is not an environmentally friendly, ecological printing type.

Transfer printing is a printing technique known as hot and dry printing. Considering the richness of patterns and colors it offers, it has become an artistic process rather than technology in recent years. The transition of transfer printing to the textile world was at the end of the 1950s, but with the rapid advancement of technology in recent years, the quality and speed in industrial applications have increased at the same rate and transfer printing applications have become widespread in the Textile World. How to Transfer Printing? Sublimation dyestuff, which is transferred to the printing paper in the transfer printing process and has the property of evaporation with heat, is transferred to the fabric using heat and pressure. By using disperse dyestuffs, the pattern or design printed on the paper is transferred to the fabric by transfer printing method. Transfer printing provides great advantages compared to known wet printing techniques.

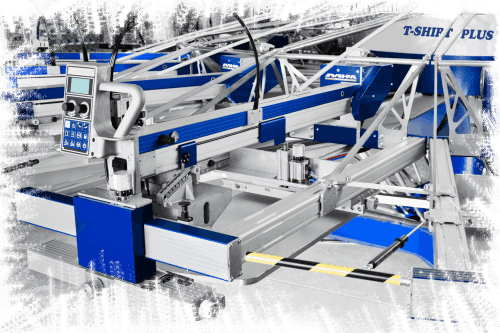

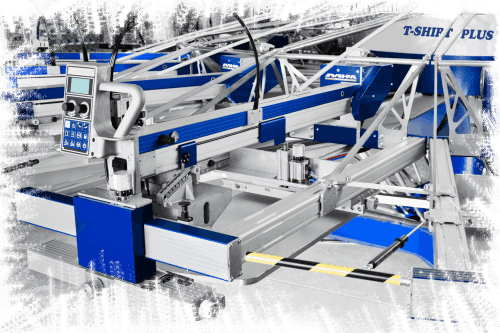

Emprime printing, which is the most widely used printing method in the textile industry worldwide, is a dye printing method with different application methods that can be preferred for both quality product production and cheap promotional product manufacturing. Water-based, plastic-based or special paints are applied to fabrics through molds. Application techniques are divided into cheap or quality varieties and many advanced applications are also available. Screen printing, silvery, luminous, embossed, etc., which provide excellent price / performance especially in low-color multi-piece works. It is also often the only solution for applying effects. While the screen printing processes are manually drawn, that is, the paints on the molds are drawn manually by squeegee, the screen printing is the application of the paint by means of industrial machines. The machines measure the stable quality, pressure, distance, etc. Thanks to the technical details, it provides much better than serigraphy. It is not possible to make some applications manually anyway.

Follow Us